What are procurement risks?

Procurement risks refer to potential challenges and uncertainties that arise when acquiring goods and services from external sources. These risks can impact a business in various ways and, if not managed effectively, can lead to financial losses, operational disruptions, unnecessary delays, and damage to reputation.

The different types of procurement risks.

The types of procurement risk that your organization is exposed to will depend on your business. For example, manufacturing companies are exposed to supply chain risks, while service companies are not dependent on securing physical goods to run their businesses.

Put another way, companies with large percentages of procurement for direct spend — that is spending on things that impact COGs — have greater vulnerability than companies with large amounts of indirect spend. Indirect spend refers to expenditures that do not impact COG and so can be considered to be more discretionary.

Financial risks in procurement.

All businesses are exposed to some financial risks in the procurement system. This is the risk where the costs that were planned for goods and services are greater than what can actually be achieved. Budget overruns hurt a company’s bottom line and if they can’t be made up in the procurement process, cuts would have to be made elsewhere.

Quality risks in procurement.

Quality risks in procurement refer to any potential threats that can compromise the quality of goods or services received by a company. These risks can have significant consequences, leading to:

- Increased costs: Defective products, rework of services that fall short, and delays can all lead to unexpected expenses.

- Loss of productivity: Time spent dealing with quality issues can divert resources from other critical tasks.

- Damaged reputation: Delivering poor-quality products or services can harm customer satisfaction and brand image.

- Regulatory non-compliance: Failure to meet quality standards can result in fines, penalties, and even product recalls.

Here are some of the most common quality risks in procurement:

Supplier-related risks:

- Supplier selection: Choosing unproven or unreliable suppliers can increase the likelihood of receiving poor-quality goods or services.

- Supplier performance: Fluctuations in a supplier’s quality control processes or production capabilities can impact the quality of your deliveries.

- Change in suppliers: Switching suppliers can introduce new quality risks, especially if proper due diligence and qualification processes are not followed.

Specification and design risks:

- Vague or incomplete specifications: Inadequate or unclear product or service specifications can lead to misinterpretations and, ultimately, unsatisfactory results.

- Design flaws: Deficiencies in the design of a product or service can lead to inherent quality issues that are difficult to rectify later.

Contract and communication risks:

- Ambiguous contract terms: Vague or poorly defined quality requirements in contracts can lead to disputes and difficulties in enforcing quality standards.

- Ineffective communication: Lack of clear communication channels and protocols between buyer and supplier can cause misunderstandings and hinder effective quality control.

Internal process risks:

- Inadequate inspection and testing: Insufficient quality control procedures during receiving, warehousing, and production can lead to undetected defects.

- Lack of training: Untrained personnel may not be able to properly assess the quality of goods or services received, increasing the risk of accepting substandard products.

- Insufficient data and analysis: Failure to track and analyze quality data can hinder the identification and mitigation of recurring quality issues.

Operational risks in procurement.

Operational risks in procurement arise from the intricate, complex, and cross-functional activities associated with purchasing. These risks can negatively affect business continuity, profitability, and reputation. We can understand and mitigate operational procurement risks by breaking them down.

Inefficient processes: Procurement workflows can devolve into a web of approvals, siloed processes, too many manual tasks, outdated data, and outdated systems. This inefficiency can result in slow turnaround times, missed deadlines, and errors. Automating routine tasks, streamlining workflows, and embracing digital solutions can improve efficiency.

Information silos: Data, the fuel of efficient procurement processes, often gets trapped in information silos. Procurement teams operating in isolation from other departments can miss crucial insights. Breaking down silos, fostering cross-functional collaboration, and implementing transparent data-sharing platforms are ways to overcome these risks.

Supply chain disruptions: With dependencies on nature, political stability, and economic predictability, supply chains can be disrupted unexpectedly and without warning. Building a diverse supplier base, implementing robust risk management strategies, and adopting agile sourcing can offset some of the risks.

Compliance missteps: Navigating regulations, laws, and ethical standards is challenging. A single misstep can result in hefty fines, reputational damage, and even legal repercussions. Staying updated on regulations, implementing robust compliance programs, and conducting regular audits of internal processes are best practices for managing these risks.

Lack of visibility: Lack of visibility into supplier performance, inventory levels, and spending patterns can lead to unpleasant surprises. Implementing real-time data analytics dashboards, tracking key performance indicators, and utilizing predictive forecasting tools are essential to get the visibility you need.

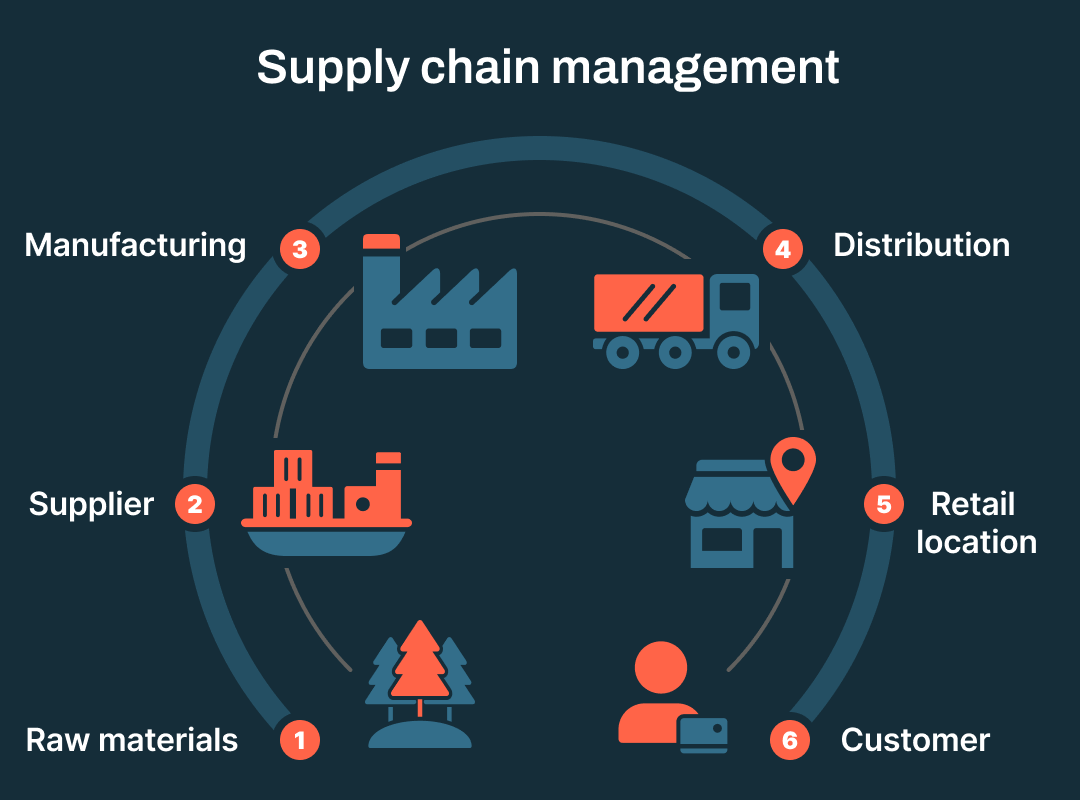

Supply chain risks in procurement.

We have all witnessed firsthand how the COVID pandemic brought the global supply chain to its knees. But supply chain risk is ever present for procurement teams, where sourcing strategies can be up-ended for several reasons.

Supply chain risks have become more prevalent and can be assessed in five categories:

Supplier dependence: When an organization relies heavily on a single or a few suppliers, a domino effect can easily be triggered. Diversifying your supplier base, developing strong alternative sources, and fostering transparent relationships with key vendors can help mitigate these risks.

Geopolitical instability: The world is highly unpredictable, and political events can disrupt supply chains. Whether it’s trade wars imposing tariffs or military conflicts disrupting transportation lanes, imports can become prohibitively expensive. Building regional sourcing strategies, understanding geopolitical risks, and developing contingency plans can help limit exposure to these risks.

Natural disasters: We have experienced an increased level of natural disasters interrupting economic activity over the past few years. Whether it’s floods crippling transportation networks, earthquakes severing key production lines, and even volcanos interrupting air traffic, more frequent and more intense natural disasters are expected. Implementing supply chain mapping tools, identifying alternative routes, and disaster recovery plans are basic best practices that should be followed.

Cyber threats: From data breaches to ransomware attacks, the digital world presents an ever-growing area of vulnerability for supply chains. Hackers can compromise your supplier’s systems, exposing sensitive information or disrupting operations. Investing in robust cybersecurity measures, conducting regular vulnerability assessments, and implementing data security protocols can help provide a layer of protection from these threats.

Economic fluctuations: Market fluctuations in the economies you purchase from can disrupt your procurement strategies. A currency devaluation could make your overseas supplier contracts more expensive and perhaps prohibitive. Proactive financial planning, monitoring economic trends, and hedging against currency and interest rate risks are some ways you can protect your budgets.

Contractual risks in procurement.

Contracts reflect the rights and obligations of parties and are important to the smooth running of all commerce. Since non-performance or non-compliance can be a matter of interpretation, it’s best not to rely on a handshake. Let’s take a look at where contracts can go awry.

Ambiguous clauses: Vague and open-ended language can lead to confusion and potential disputes. Take, for example, a delivery deadline with no clear specification — where missed delivery can cause financial harm. Precisely defined key terms, responsibilities, and timelines in your contracts, with no room for misinterpretations, improve communication, business relationships, and business outcomes.

Uneven risk allocation: Contracts that tip the scales of responsibility unfairly by expecting one party to bear the brunt of losses due to unforeseen circumstances can end up in court. It’s best to negotiate fair and balanced risk allocation, considering factors like supply chain risk management, disruptions, force majeure events, and intellectual property rights to make your contracts ironclad.

Inadequate performance metrics: Without clear benchmarks for quality, performance, and delivery, monitoring contract performance is impossible. Left to interpretation, each party will interpret the contract according to their own interests. Measurable and quantifiable performance metrics will make expectations crystal clear for all parties.

Hidden costs and fees: Often buried deep within contracts or obscured with convoluted language, surprise fees can damage any business transaction. For example, you might unknowingly accrue storage charges due to unclear delivery terms. That’s why it is important to scrutinize every contract section, paying particular attention to hidden fees, termination clauses, and change order provisions.

Outdated terms and conditions: Contracts that have been negotiated with suppliers can age quickly in today’s ever-changing world. Regularly review and update your contracts to stay abreast of changing regulations, market trends, and technological advancements.

These contractual risks are present every time you sign an agreement, whether they are acknowledged or not. Recognizing them allows you to monitor and take action early before losses can mount.

Guided Procurement Tour

Explore our automated procurement workflows in the Guided Procurement interactive tour.

Procurement risk management strategies.

A well-equipped procurement team can harness powerful strategies and procurement technology to measure and manage exposures to risk. Here are some ways that procurement teams manage these risks.

Supplier diversification: Relying heavily on a single supplier can be catastrophic for a business. The best risk management strategy is to build a diverse supplier network. This way, if one supplier fails, you are already prepared to contract with another.

Risk mapping and assessment: As we’ve mentioned, risk identification and risk assessment are the first and possibly most important steps. Identify potential risks in your supply chain, from geopolitical turmoil to natural disasters. By understanding these risks, you can develop targeted mitigation strategies and build resilience.

Data-driven decision-making: Embrace the power of data by ensuring you have access to good data. Leverage analytics to predict market fluctuations, track supplier performance, and optimize inventory levels. Data relies on good collection techniques, and harnessing it requires good software for the models.

Contractual vigilance: Contracts are meant to protect your purchases. Scrutinize every clause, ensuring clear terms, balanced risk allocation, and well-defined performance metrics. Good contracts eliminate confusion and save time and money.

Technology adoption: Technology is key to successful risk management. Automated workflows streamline approvals, reduce errors, and free up resources for strategic risk management. Cloud-based platforms provide real-time data visibility, allowing you to monitor potential threats and react swiftly.

Communication and collaboration: Foster open communication with suppliers, internal teams, and external stakeholders. This collaborative spirit builds trust, allows for early detection of risks, and facilitates joint mitigation strategies.

Proactive resilience: Build risk mitigation plans into your procurement processes. Proactive strategies like alternative sourcing, buffer inventory, and disaster recovery plans turn potential disasters into manageable events with minimal impact on your business.

Continuous improvement: Risk management requires ongoing attention. Regularly review your strategies, analyze past incidents, and adapt to a changing landscape.

Integrated risk and vendor management.

Proactive strategies to manage vendor risk and ensure smooth and secure operations include the following areas.

Vendor selection: A rigorous vendor management and selection process includes meticulously evaluating factors like financial stability, quality control systems, security practices, and ethical considerations. Choose reliable partners who share your values and your goals.

Performance monitoring: Regularly monitor vendor performance against agreed-upon metrics, including delivery times, quality standards, and pricing agreements. Utilize data analytics to identify potential performance dips and address them promptly.

Contractual clarity: Craft comprehensive contracts that outline expectations, responsibilities, risk allocation, and performance penalties. Minimizing room for disputes and safeguarding your interests.

Collaborative communication: Foster open communication and collaboration with your vendors. Regular meetings, clear communication channels, and joint problem-solving sessions build trust, strengthen relationships, and allow for early detection and mitigation of potential risks.

Cyber vigilance: Conduct regular security audits of your vendors’ systems, enforce data protection protocols, and ensure secure communication channels to safeguard your sensitive information.

Risk diversification: Build a diverse vendor network, strategically spreading your dependence and minimizing the impact of potential disruptions from any single vendor.

Regular assessments: Periodically re-assess your vendor risks based on changing market conditions, internal needs, limited resources, and vendor performance. Adapt your strategies and update your vendor roster as needed to maintain a resilient and sustainable vendor supply chain.

Contractual risk mitigation.

From ambiguous clauses to hidden penalties, a bad contract can poison the best business relationship. Striving for fair and balanced contracts can lead to healthy, long-term procurement collaborations.

Eliminate ambiguity: Prioritize crystal-clear language in your contracts, leaving no room for misinterpretations. Precisely define terms, responsibilities, timelines, and acceptance criteria.

Balance the burden: Negotiate contracts that allocate risks equitably, considering factors like supply chain disruption, vulnerabilities, force majeure events, and intellectual property rights. Good contracts ensure that neither party gets snagged by unexpected burdens.

Metrics add clarity: Without clear benchmarks, performance becomes a guessing game. Establish measurable and quantifiable metrics for quality, delivery, and service provision.

Make the hidden known: Scrutinize every contract section to understand potential hidden costs, termination clauses, and change order provisions.

Get a good lawyer: Seek counsel from legal professionals to ensure your agreements are watertight and stand up to scrutiny. In some cases, specialist legal skills may be required.

Predictive spend risk analysis.

Procurement, like many other business practice areas, faces unpredictability. This include unanticipated price hikes or hidden supplier fees and can derail carefully planned budgets. But a reliance on the emerging science of predictive analytics can empower businesses to foresee potential spend risks and proactively prepare countermeasures.

Seeing into the future:

Predictive analytics leverages historical spending patterns, market trends, supplier behavior, and external factors like economic forecasts to anticipate potential cost overruns, material shortages, or supplier disruptions.

Proactive steps:

Taking action sooner can lead to better outcomes. This can include ones we have already advised like diversifying the supply chain but also negotiating buffer zones, optimizing inventory management, and implementing cost-saving strategies.

Building a predictive capability:

Harnessing the power of predictive analytics requires effective implementation:

- Data: Ensure access to accurate and comprehensive data on past spending, supplier performance, and relevant market trends.

- Invest in software solutions: Utilize robust software specifically designed for procurement analytics, offering functionalities like scenario planning, risk visualization, and real-time data updates.

- Upskill your team: Train procurement teams to interpret and act upon the insights gleaned from predictive analytics, ensuring effective risk mitigation strategies.

Transparency-driven compliance assurance.

By shedding light on every step of the procurement process, businesses can ensure compliance.

Compliance confidence: Regulations and industry standards exist for a reason. They protect everyone from unethical practices and ensure fair competition. Yet, navigating their complexities can be a challenge. By making procurement processes transparent, businesses provide clear evidence of their commitment to compliance. This fosters trust with regulatory bodies, reduces audit risks, and minimizes the potential for costly fines and penalties.

Building trust and credibility: Building trust with stakeholders enhances a company’s reputation, attracting ethical suppliers and attracting and retaining customers who value responsible business practices.

Collaboration and shared responsibility: When procurement processes are transparent, all stakeholders — from internal teams to suppliers and auditors — can play a role in identifying and mitigating risks. This collaborative approach leverages collective knowledge and empowers everyone to act as compliance champions.

Technology-enabled compliance: Automation and digital tools illuminate the procurement landscape. E-procurement platforms provide centralized and auditable records of all transactions, while data analytics offer real-time insights into potential compliance risks. By embracing technology, businesses can move beyond the manual processes of tracking and excel in transparent and streamlined procurement practices.

Strategic supplier risk partnership.

Forging strategic supplier partnerships is a highly effective strategy for managing procurement risk. By openly sharing information, businesses and suppliers can predict and proactively mitigate risks.

This collaborative foresight leads to smarter sourcing, optimized inventory, and resilient operations. Working in partnership leads to stronger vendor relationships, reduced costs, and a path toward shared success. When your suppliers are an integral part of your company’s success, forging strong relationships can be pivotal to improving your company’s performance and, at times, help it weather serious challenges.

Data-driven technology resilience planning.

Resilient procurement thrives on data and tech. Real-time insights predicting market shifts, supplier risks, and inventory needs all help with the planning process. AI-powered analytics anticipate disruptions, suggesting alternative sources and optimizing stock levels. But it’s not just data — automation streamlines approvals, reduces errors, and frees up resources for strategic risk management. So, integrate data dashboards, embrace cloud platforms, and train your teams to wield these tools.

Schedule a demo

Learn how Airbase can transform your entire purchasing process.

Jira Integration – Streamline Your Workflows

Jira Integration – Streamline Your Workflows  Ironclad Integration – Simplify Legal Operations

Ironclad Integration – Simplify Legal Operations  Asana

Asana